At this point, we figured what we were facing were countertop materials composed of both acid soluble minerals like calcite (found in marble and limestone) folded together with harder, non reactive minerals like quartz (the predominant mineral in quartzite). At the same time, having worked on true quartzite, it was perplexing to witness such a wide gap in durability. The answer? it wasn't quartzite to begin with.

Metamorphic stone types (including marble, quartzite and granite) are the result of minerals and other impurities being pressed together under extreme heat and pressure, impurities give us the varieties of colours we see, but the main mineral compositions result in drastic differences in hardness and acid solubility. Marble is made up of a mineral called calcite. Calcite results from the chemical compound calcium carbonate. Dolomite, another mineral, is made of calcium magnesium carbonate. This dolomite mineral makes for a stronger, but still etch prone cousin of marble, called dolomitic marble. While dolomitic marble is harder than standard marble, and less prone to etching, it is nowhere near the strength of actual quartzite. Visually, all three of these stone types can show very similar colours, patterns and grain, making visual identification unreliable.

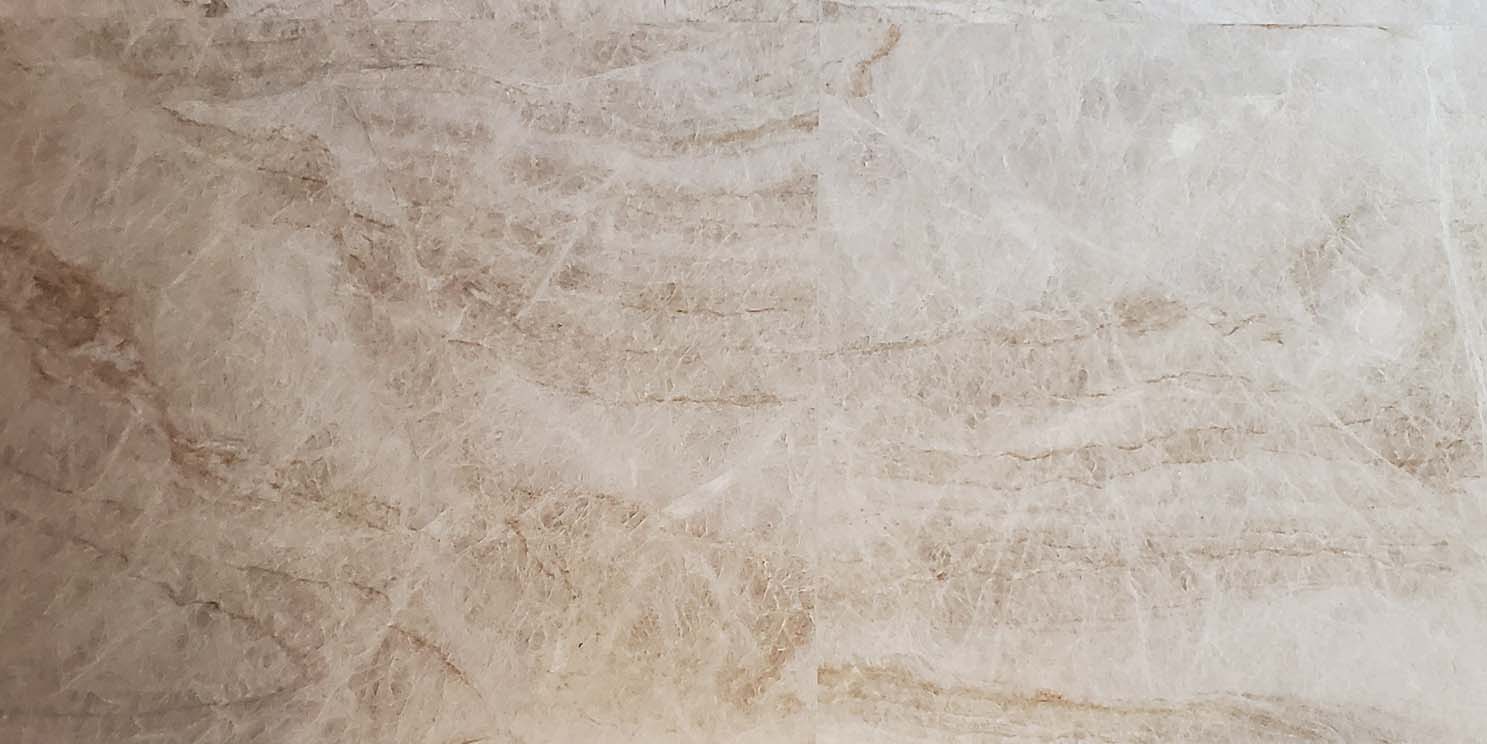

The first image shows a dolomitic marble sold as "quartzite" but nearly as delicate as marble. The Second is true quartzite, an extremely durable material significantly stronger than both marble and granite. Take note of their visual similarities.